Exhaust Systems for Proper Air Management in Commercial Kitchens and Adjacent Areas

Air extraction systems or Exhaust Systems in professional kitchens are very important for proper air circulation. With proper air extraction, unpleasant circumstances in working environments can be reduced and prevented, and the safety of workers and customers seated in adjacent rooms can be ensured.

Exhaust Systems: Their Purpose

Exhaust systems forcibly extract air that has become heavy, hot, and humid due to cooking fumes and automatic dishwashing. This air is then expelled outside.

With exhaust systems, it is possible to prevent odors from stagnating in kitchens and adjacent areas, as well as the formation of humidity, condensation, and mold on walls and ceilings. Additionally, these systems prevent unpleasant droplets from falling onto food, workers, and various equipment, thus avoiding contamination.

Exhaust systems must be capable of managing, monitoring, and maintaining the following parameters according to current regulations:

- Airflows

- Temperature 25°/30°

- Humidity level

- Air conditioning

- Filtration of incoming and outgoing air

- Capture and extraction of grease and fumes

- Noise pollution control

Types of Exhaust Systems: Localized Capture and Displacement

There are various types of exhaust systems, but all models forcibly direct air outside, inevitably impacting air movement, quality, temperature, and humidity. In essence, all exhaust systems influence ventilation, thermoventilation, and the overall climate control of the environment where they are installed, as well as connected adjacent areas via doors, windows, and air vents.

The main categories of exhaust system types are:

- Displacement Systems: Installed in ceilings that become extractor surfaces, creating a widespread and uniform airflow over the entire or primary surface of a professional kitchen.

- Localized Capture Systems with Hood Terminals: These systems act locally above equipment to block fumes.

Depending on their operational characteristics, hood-based exhaust systems are divided into

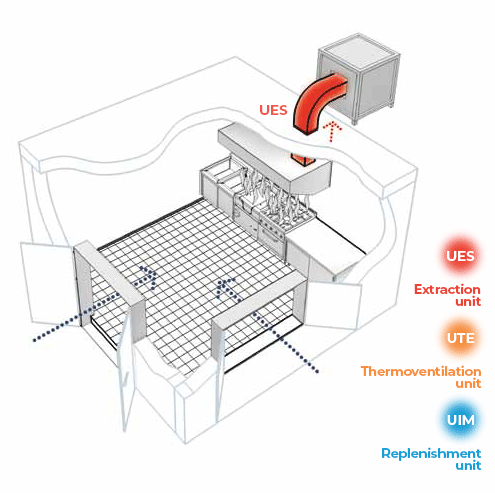

A. Simple Extraction System

-

Functional Mode

Air extraction

-

System Elements

Hood, extraction unit, control panel, ducting

-

Pros

Low cost, simple installation and maintenance

-

Cons

The depression created for simple air extraction draws air from outside and adjacent areas through doors and windows. This can lead to unexpected drafts, chimney draft issues, and thermal imbalances (especially in winter), causing further inconvenience for kitchen staff and customers.

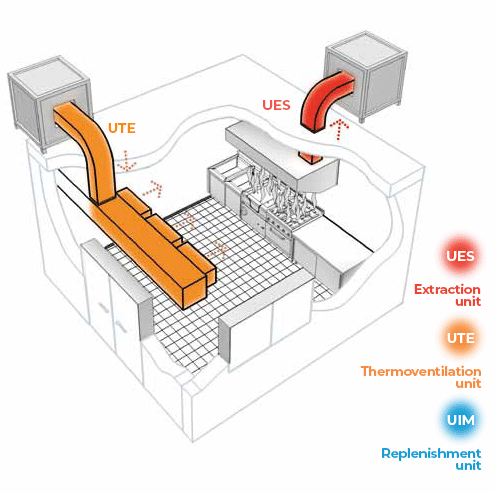

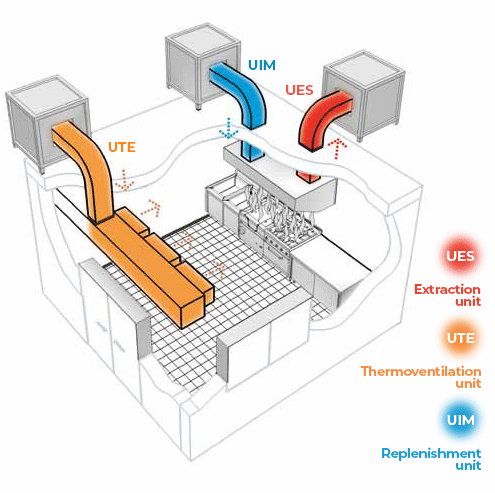

B. Extraction System with Air Replenishment in the Environment

-

Functional Mode

Air extraction and replenishment in the environment

-

System Elements

Hood, extraction unit, thermoventilation unit, temperature regulator, control panel, ducting, air inlet conduits

-

Pros

Controlled air movement and temperature in the kitchen environment

-

Cons

High operational costs due to frequent air exchanges and the thermal treatment of incoming air

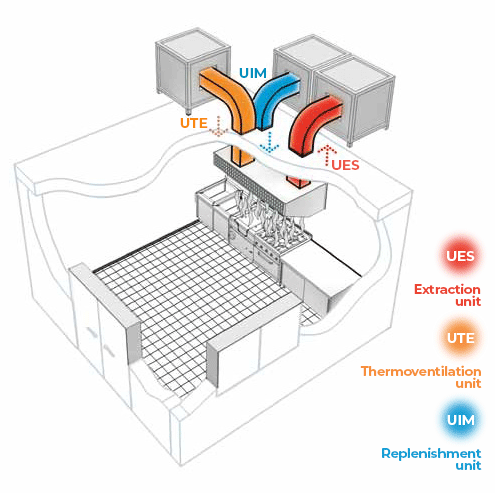

C. Hood Compensation System

-

Functional Mode

Air extraction and replenishment within the hood

-

System Elements

Hood with inductor, extraction unit, replenishment unit, control panel, ducting

-

Pros

Lower frequency of air exchanges compared to environment-only compensation. Better fume capture due to the inductive effect of the introduced air directed towards filters, which operate efficiently due to the lower operating temperature.

-

Cons

Unexpected drafts, chimney draft issues, and thermal imbalances due to treated air being drawn from the dining area.

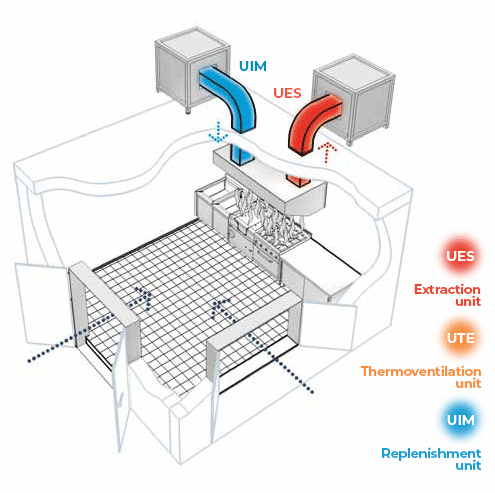

D. Compensation System with Air Replenishment in the Environment

-

Functional Mode

Air extraction and replenishment within the hood with environmental thermoventilation

-

System Elements

Hood with inductor, extraction unit, replenishment unit, thermoventilation unit, temperature regulator, control panel, ducting, air inlet conduits

-

Pros

Lower frequency of air exchanges, no drafts, good fume capture, and consequently better filter efficiency, controlled air movement and temperature in the kitchen environment, lower operational costs

-

Cons

Higher installation and system costs

E. Compensation System with Air Replenishment at the Hood Edge

-

Functional Mode

Air extraction and replenishment within the hood with environmental thermoventilation from the hood edge

-

System Elements

Compensated flow hood with induction, extraction unit, replenishment unit, thermoventilation unit (or heat exchanger), temperature regulator, control panel, ducting

-

Pros

Less frequent air exchanges, controlled air movement and temperature, better filter performance, and lower operational costs. Improved aesthetic impact due to the elimination of treated air inlet ducts. Better fume capture and filter efficiency, controlled air movement and temperature, lower operational costs. Absence of treated air inlet ducts enhances the environment's aesthetics.

-

Cons

Higher installation and system costs, but lower compared to remote air replenishment solutions in the environment compared to the hood.

Choosing the Right Exhaust System

When a restaurant, hotel, canteen, or any establishment dedicated to food service needs to equip their kitchen with a professional exhaust system, they should consider the following factors in addition to consulting with professionals and experts in the field:

- Total volume of the spaces

- Number of occupants

- Level of natural ventilation already present

- Presence and position of openings like doors and windows

- Number of air exchanges required per hour

- Amount of available electrical power

When a Localized Capture System is Mandatory

If equipment with gas systems and cooktops with a capacity exceeding 15 kW are present, regulations require exhaust systems with hoods. Therefore, the correct hood size, which depends on the dimensions of the underlying equipment and the volume of the entire room, must be considered.

In other cases, extractor ceilings and filter ceilings can be adopted as air extraction systems in professional kitchens.

For any doubts about current regulations, it is always advisable to consult with industry professionals.

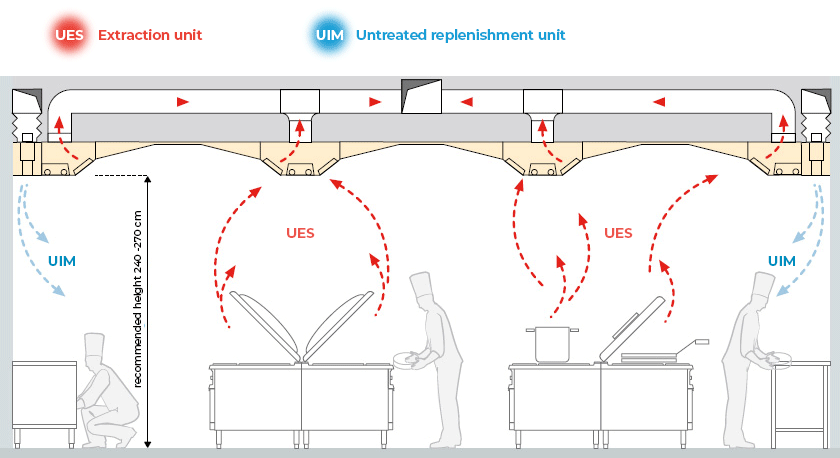

Advantages of a Displacement Exhaust System

Displacement exhaust systems are not only efficient but also aesthetically more appealing compared to traditional or compensation hoods. Like hoods, extractor ceilings can be custom designed for any kitchen environment. However, unlike hoods, this ventilation system allows for the free movement of kitchen equipment, optimizing space whenever equipment is replaced or expanded.

Additionally, wall-to-wall installation allows for complete cleaning of filters and stainless steel surfaces without gaps and optimizes air conditioning and airflow within an environment.

When displacement exhaust systems are used in large kitchens and food preparation centers, the consumed air, filled with vapors and greasy fumes, is drawn by thermal differential and depression towards the false ceiling or ceiling. Here, separation traps capture grease particles. The purified air then diffuses into the false ceiling space and is extracted to be released outside through an exhaust channel.

Displacement Exhaust System and Lighting

If a displacement exhaust system is chosen to purify the air in kitchens, the lighting of the environment should also be planned to integrate into the ceiling during the design phase.

Benefits of a Displacement Exhaust System

In summary, the benefits and advantages of a hoodless exhaust system can be summarized as follows:

- Energy savings

- Complete ventilation without drafts

- Optimal microclimate in the environment

- Rapid odor elimination

- Attractive design

- Ease of cleaning

- Free movement of equipment

- Easily accessible space above the false ceiling

- Extreme quietness with reduced noise from kitchen operations

If you want to purchase an exhaust system and need more information, contact the Cook-In team. We are always available to advise you on the most suitable custom solutions for your needs.