Air Treatment and the Extractor Ceiling

The efficiency of the hood or extractor ceiling is closely linked to the performance of a kitchen’s ventilation and air conditioning systems.

When considering equipment for a professional kitchen, people typically think of cooktops, ovens, blast chillers, and refrigeration units. Hoods and, more broadly, all equipment for extracting smoke and steam are often viewed as a separate matter. However, the efficiency of the hood or extractor ceiling is integral to the performance of the kitchen’s ventilation and air conditioning systems. It is essential to create a comfortable environment that enables staff to work effectively and produce high-quality results.

There is even a European technical standard, UNI EN ISO 7730, that establishes how to calculate the thermal sensation perceived by a person in an enclosed environment: whether they feel comfortable, too hot, too cold, or experience discomfort caused, for instance, by drafts, temperature differences between the feet and head, or exposure to heat or cold sources that create an asymmetric warm-cold feeling. This is known as the thermal ergonomics of the environment, which is just as important as workplace ergonomics — the layout and arrangement of equipment designed to facilitate operations and reduce staff fatigue.

A study conducted in the United States across a hundred professional kitchens, from fast-food joints to Michelin-starred restaurants, revealed that most staff, in both summer and winter, are exposed to conditions that fall outside ISO standard thermal comfort. This means that while attention is rightly given to workflow, ease of equipment use, and counter height, the crucial element of properly designed exhaust systems for smoke and steam is often overlooked.

Moreover, these systems have a significant impact on energy bills. According to a study by the US Green Restaurant Association, kitchen climate control accounts for 17% of the energy consumption in restaurant operations, while extraction and ventilation account for another 11%. Considering that the entire US foodservice sector incurs an energy bill of $10 billion annually, with $8 billion going to kitchen operations alone, it is estimated that approximately $2.15 billion is spent each year on air treatment in professional kitchens. In Italy, where a restaurant’s average annual electricity bill is about €9,000 (according to 2013 data from Ascomac), in the kitchen air treatment costs can reach nearly €2,500 annually. This is often due to the separate design of air conditioning and extraction systems, sometimes managed by different companies, leading to inefficiencies and increased expenses. The US Green Restaurant Association notes that simple measures could cut these costs in half. There’s no reason why the same approach couldn’t be applied in Italy.

What Can Be Done? Approaches to air treatment in professional kitchens have evolved over time. It’s crucial to work with companies and designers who thoroughly understand the topic and are often also suppliers of other kitchen equipment. Previously, the standard practice was to install a dedicated hood for each piece of equipment that produced cooking fumes. This approach is becoming less common, particularly when many devices are used separately within a space, such as cooktops, ovens, salamanders, fryers, and pasta cookers. The current prevailing approach treats the kitchen environment as a single system. This means that instead of multiple extraction devices for each cooking appliance, a single system is installed: the extractor ceiling, custom-designed and scaled to handle the total output of smoke and steam generated by all kitchen equipment.

Building such systems requires adherence to specific standards and expertise that only thorough knowledge of the field and technology can provide. It’s essential to rely on specialists. For example, the sections of the extractor ceiling ducts, their intersections, and the materials used must follow strict guidelines. Errors in calculations or even assembly can lead to functional issues that negatively impact staff work and operating costs. Cooking vapors and smoke are saturated with grease, which can accumulate inside ducts and cause dripping at junction points if improperly constructed.

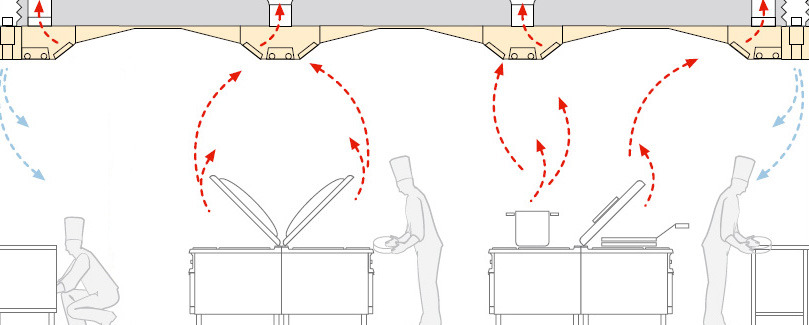

An important aspect is calculating the volume of air extracted from the kitchen and its replacement. Simply expelling air can create a pressure differential between the kitchen and adjoining areas, including the dining room, causing drafts and the flow of air-conditioned or heated air. Such drafts are not only uncomfortable for guests but also increase energy costs as air conditioning systems are forced to work harder. The latest extractor ceiling technology is “compensation” type, where the air removed from the kitchen is balanced by air drawn from outside. This incoming air is filtered and often passed through heat exchangers that transfer some of the thermal energy from the outgoing air to the incoming air, preventing temperature fluctuations in the kitchen.

Another technology is the induction extractor ceiling, which, in addition to external air replacement, introduces part of the extracted air at a specific speed, calculated to mix evenly with the existing air in the kitchen. This avoids drafts or discomfort for staff, ensuring ideal working conditions.