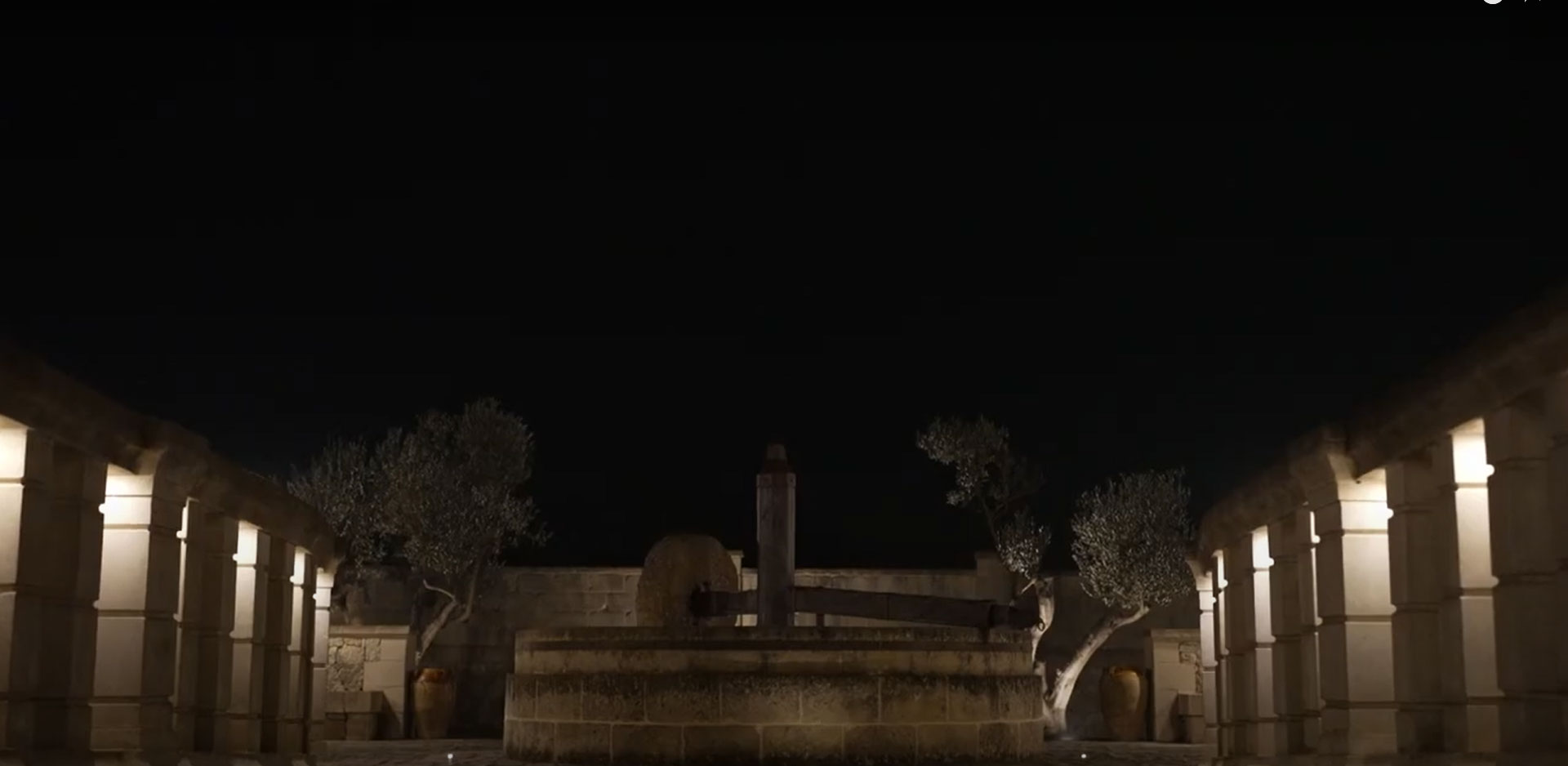

Agritourism Kitchen Design Tenuta Manca Lizzanello (LE)

Technical Sheet – Agritourism Kitchen Design

Client: Tenuta Manca

Address: Lizzanello (LE)

OBJECTIVE:

The design and construction of the new kitchen at the Tenuta Manca agritourism aimed to optimize workspace and improve operational efficiency. The main goal was to ensure a functional, safe environment compliant with current regulations, with an optimal division of preparation, cooking, and washing areas.

REQUIREMENTS:

To achieve the set objective, several key requirements were addressed:

- Space optimization: The kitchen layout was designed to maximize the use of available space, ensuring a logical arrangement of equipment and workstations.

- Functional separation: The washing area was separated from the preparation and cooking areas to prevent contamination and improve overall kitchen hygiene.

- Professional equipment: The kitchen was equipped with suitable tools and furnishings to prepare a full menu, including dedicated areas for appetizers, first courses, and main courses.

- Optimized workflow: The movement of kitchen staff and waiters was organized efficiently to avoid congestion and enhance service quality.

- Compliant technological systems: New electrical and plumbing connections were installed to safely and efficiently support equipment operations.

- Advanced ventilation system: A highly effective ventilation system was essential to ensure a healthy and comfortable environment by removing smoke and odors.

SOLUTION:

To meet the agritourism’s requirements, the project included:

- Strategic layout: Workstations were divided functionally, with dedicated areas for preparation, cooking, plating, and washing, ensuring efficiency and safety.

- Separation of the washing area: A distinct area was created for dishwashing and waste disposal, reducing the risk of contamination between waste and food preparation.

- Installation of professional equipment: Stainless steel workbenches, professional stoves, high-efficiency ovens, large refrigerators, and industrial dishwashers were supplied.

- Optimized workflow: Specific routes were designed for kitchen staff and waiters, minimizing overlap and improving service speed.

- New electrical and plumbing systems: Modern and safe connections were implemented, designed to support the energy load required by professional kitchen equipment.

- Efficient ventilation system: A professional hood with activated carbon filters and ventilation ducts was installed to maintain a smoke- and odor-free work environment and enhance safety.

ADVANTAGES:

- Improved operational efficiency: With the division of work areas and optimized workflow, staff can work quickly and in an organized manner, reducing preparation times.

- Enhanced hygiene and safety: The separation of work zones ensures optimal space management, reducing the risk of food contamination.

- Reduced waiting times: Thanks to efficient organization, customer service is faster, enhancing the overall agritourism experience.

- Greater comfort for staff: The installation of a proper ventilation system and ergonomic equipment layout improves working conditions for kitchen operators.

- Adaptability and regulatory compliance: The project was developed to meet hygiene and safety regulations, ensuring a work environment that adheres to required standards.

TIMELINE

The project was completed within 10 weeks, including design, installation, and commissioning of the new agritourism kitchen.